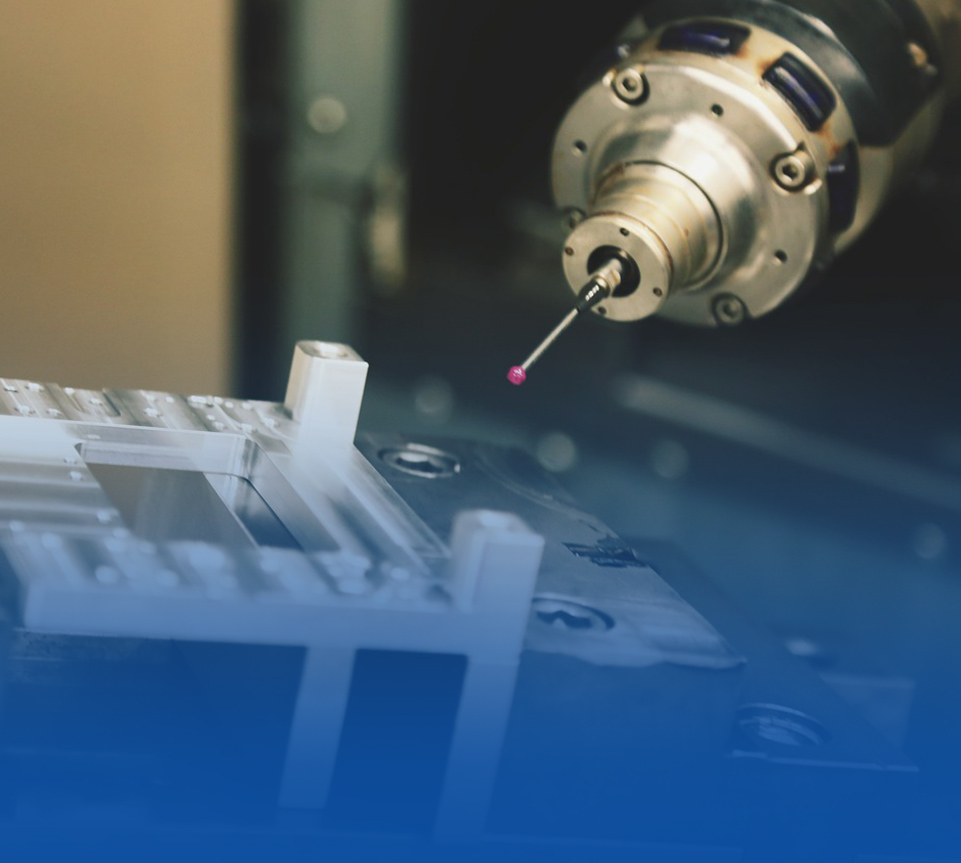

High-end CNC machine tools

Go back

Application overview

CNC machine tool is a kind of automatic machine tool equipped with a control system, with high precision, good flexibility, high efficiency, function compound, intelligent control, and other characteristics, is the mainstream direction of machine tool modernization development.

The displacement sensor is the core component of the CNC machine tool. By adding a high-precision time-grating displacement sensor on the moving shaft, real-time tracking and observing the cutting error, using the position feedback for full closed-loop control, to achieve high-precision, high-efficiency, and high-quality parts processing, and further improve the machining performance of CNC machine tool.

The displacement sensor is the core component of the CNC machine tool. By adding a high-precision time-grating displacement sensor on the moving shaft, real-time tracking and observing the cutting error, using the position feedback for full closed-loop control, to achieve high-precision, high-efficiency, and high-quality parts processing, and further improve the machining performance of CNC machine tool.

Main application equipment

customer case